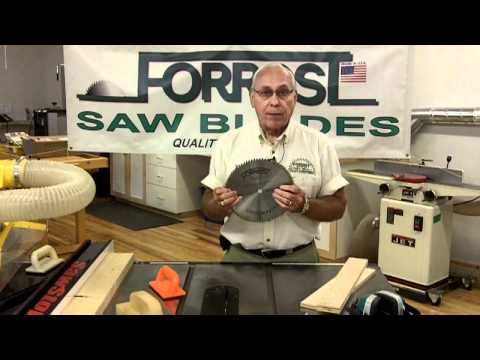

If you're looking for the finest dado set on the market, look no further than the 8" Dado King from Forrest Manufacturing. The Dado King features all the same quality and precision found in Forrest blades. Each outside cutting blade is 8” in diameter with 24 precisely ground C4 carbide teeth. The chippers are the 4-wing type, again equipped with the same high quality C4 carbide teeth. Includes four 1/8" chippers, one 3/32" chipper, and one 1/16" chipper. With various combinations, dadoes from 1/4" through 29/32" in width are possible and can be set to precise widths with the included magnetic shim set. Also includes high impact storage case.

- 24 precisely ground C4 carbide teeth

- 4-wing type chippers

- Includes four 1/8" chippers, one 3/32" chipper and one 1/16"chipper

- With various combinations, makes dadoes from 1/4" through 29/32" in width

- Magnetic shim set