$100.00

All Levels

Woodturning Basics: Bowl -- CLS312

with Ken BurtonWednesday, October 1, 5:30 PM - 8:30 PM

Explore the possibilities of bowl turning as you learn to use a bowl gouge to turn your first bowl.

Explore the possibilities of bowl turning as you learn to use a bowl gouge to turn your first bowl.

This is a introductory course to CNC. Students will learn the basic components of a CNC machine and fundamentals of how to design and machine a simple sign.

Get started at the lathe by learning the basics of spindle turning. In this exciting hands-on class you'll learn the skills required to start making spindles on the lathe as you turn two objects: a cove and bead stick and a vase. Tools covered include the roughing gouge, the spindle gouge, and the parting tool.

Sharp tools make all the difference in woodworking. However, it’s a fact that nearly all new woodworking chisels and plane irons are not ready to use. Once they’re properly sharpened, your woodworking skills will improve. In this class, you will learn how to put a truly keen edge on your tools using the Flat Sharpening method. We will teach you how to sharpen your chisels and plane iron blades. All you need to bring are typical tools you would like to sharpen; chisels or hand plane iron blades.

This is a introductory course to VCarve software used for designing projects for CNC. Students will learn the fundamentals of creating and machining a project on CNC.

Face Frame cabinets are one of the most widely used cabinets. The face frame is attached to the front of the cabinet box (carcass) and the cabinet doors cover the opening of the face frame. Students will be making a cabinet carcass along with the face frame using specific joinery methods to assure solid construction. Students should be prepared for hands-on use of the table saw, router, Kreg Pocket Hole Jig, clamps and other miscellaneous woodworking tools. Skills developed in this class will apply to many other woodworking projects. Students will be able to take the completed cabinet home.

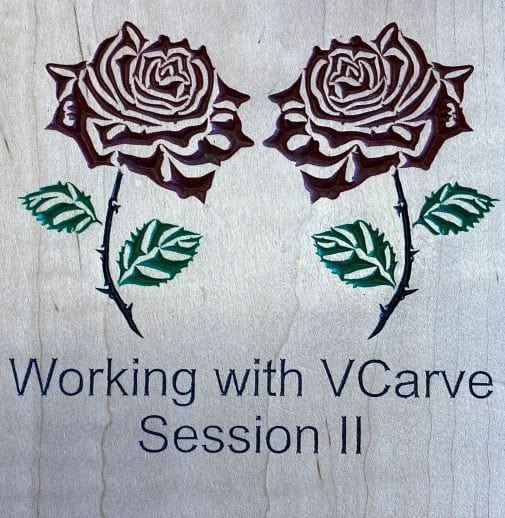

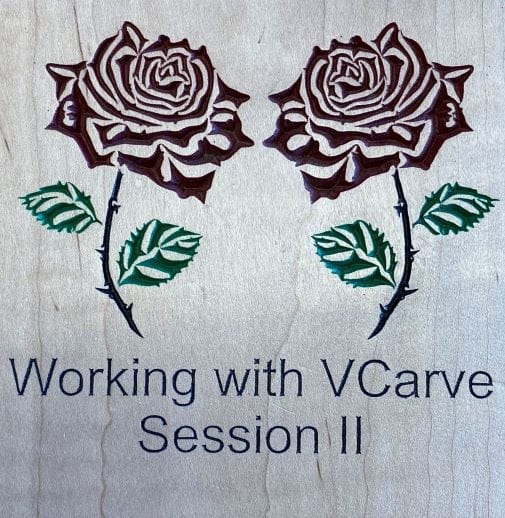

This is the 2nd class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use layers, import files, edit vectors, manipulate text and combine multiple toolpaths into one file. The student will design and carve a picture.

Learn the basics of woodcarving as you create a stylized bird figurine. Topics covered: tools to use including knives, chisels, and carving burrs; sharpening; work holding; wood selection; reading the grain; and more. Participants need to have or purchase a small carving knife such as Flexcut’s model KN13 (#814267) or KN12 (#814266) or/and a Kevlar safety glove (#06I63-other sizes available—you’ll only need one, not a pair)

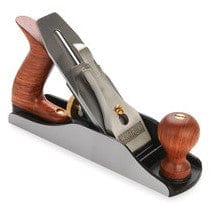

Learn how to select, sharpen and use one of the most misunderstood tools in the shop. Various types of hand planes, uses, tuning, sharpening and care will be covered. Bring your own hand plane or use one of ours.

This is the 3rd class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use Transform Function, dimension work, use guidelines, use Tabs, design and machine a gear.

This is the 4th class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use design 3D project, import 3D objects, manipulate 3D objects, create a toolpath and machine a 3D model.

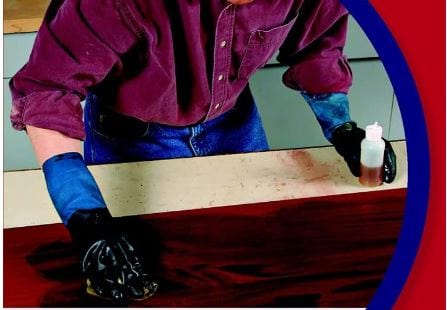

Featuring General Finish's new products. Wipe-on and brush-on both oil and water based finishes for the small-shop woodworker. The instructor will go over most of the General Finishes line of products with "how to prepare" instructions along with the advantages of the various products. In this class, you'll find out which finishes work best for particular applications, and how to apply them to achieve a lustrous sheen that begs to be touched and that scoffs at dirt and moisture.

Want to take your CNC knowledge to the next level? Learn to enhance you CNC projects and signs with inlays using contrasting colors. In this class you will learn how to prepare your project for inlaying and creating the inlay to fit your project.

This Course will cover various aspects of using routers, the class will review the router and components, various bits, proper adjustment, operation and safety of the router.

Cutting dovetails using hand tools is a very satisfying process. Dovetails are the strongest mechanical joint in woodworking and very pleasing to the eye. Learn the process of cutting perfectly fitting joints. Learn how to prepare your stock, layout for the cuts and the tools to use.

In this course you will learn to identify the different types of scroll saws, the different types of blades and to understand what blade is used for different materials. You will learn the basic operating principles including, changing blade tension, and blade speed and table angle. You will also learn proper safety including basic shop safety, personal safety and safe procedures using the scroll saw. This is a hands on class where you will learn how to make different types of cuts and make some simple projects that you can take home.

This is a introductory course to CNC. Students will learn the basic components of a CNC machine and fundamentals of how to design and machine a simple sign.

This is a introductory course to VCarve software used for designing projects for CNC. Students will learn the fundamentals of creating and machining a project on CNC.

This is the 2nd class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use layers, import files, edit vectors, manipulate text and combine multiple toolpaths into one file. The student will design and carve a picture.

This is the 3rd class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use Transform Function, dimension work, use guidelines, use Tabs, design and machine a gear.

This 2 day class you will expand your turning skills as you make an exquisite hollow form capped with a contrasting lid. Techniques to be covered include turning interior hollows, making finials, and sizing mating parts.

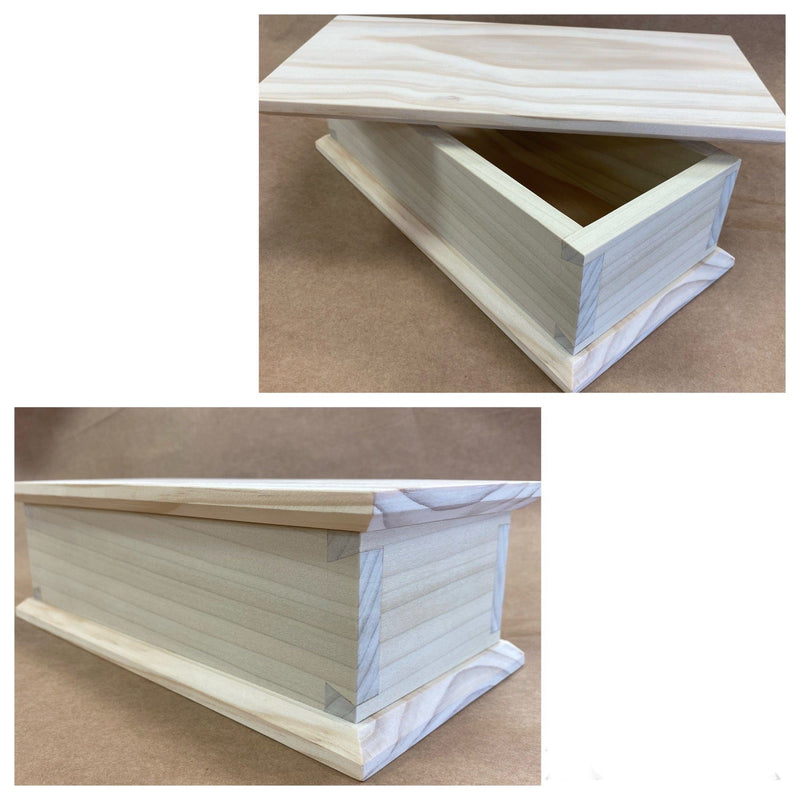

Build upon your skills learned in Handcut Dovetail CLS416 to make a simple and charming handcut dovetails keepsake box. Pine and Popular construction. Dimensions 11" long x 5 1/2" wide x 3 1/2" high.

In this class you will prepare stock, prepare a casting mold and turn to a finished project. Preparing stock consist of cutting and/or sanding stock to fit into your casting mold. Prepare the casting mold consist of assembling, sealing and coating the mold to accept the casting resin. The prepared stock and mold will be placed into a pressure pot with the required pressure for a duration of time. The project will be turned and sanded to a finished grit, parted off the lathe and then polished to a glossy smooth finished. You will be turning a previously poured resin blank. The resin blank you will pour in the class will be used for the next upcoming class.

This is the 4th class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use design 3D project, import 3D objects, manipulate 3D objects, create a toolpath and machine a 3D model.

Want to take your CNC knowledge to the next level? Learn to enhance you CNC projects and signs with inlays using contrasting colors. In this class you will learn how to prepare your project for inlaying and creating the inlay to fit your project.

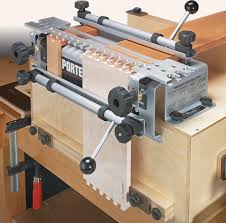

Dovetail Jig In this class you learn about the anatomy of the dovetail jig and its application. The templates, router, router bits and guide bushings. A brief discussion about the various other dovetail jigs on the market. The dovetail jig we will use in the class is the Porter Cable 4200 series. Explain the dovetail types and their usage, such as through, half blind, variable space, sliding and box joints. We will discuss stock material and its layout for cutting dovetails. Also we will discuss the safety aspects of using the dovetail jig and its components.

Learn to make decorative, jointed boxes using the Incra IBox Jig. Set up and box construction will be done on the Tablesaw.

This class is designed for a full day of turning. In the morning you turn a Pen and the afternoon you turn a bowl. Pen Turning Description: You can make the great looking pens, ones that are as unique as those available in fine gift shops. Learn the tips and techniques that produce excellent results every time. You will be shown how to cut, drill, square the ends, turn, sand, apply a durable finish quickly and then assemble the parts. You start with a raw piece of wood, a pen kit with hardware, a Mini Lathe, and by the end of class you have a beautiful, functional piece of woodworking that you did yourself. Learn the fundamentals of creating a pen from wood selection, tool selection and proper lathe techniques to finishing. Soon you will be making pens for all your friends. Bowl Turning Description: Each student will turn a bowl. Blanks will be mounted and the outside shaped including a tenon. The blank will be reversed and held in a chuck while the inside is hollowed and smoothed. The blank is finally reversed to turn away the tenon. Students will practice the cuts appropriate for shaping and smoothing the inside and outside using a bowl gouge and a scraper. At the end of class students should be able to turn a bowl on their own.

Students will learn about the different router tables and fence systems available. In addition, students will develop an understanding of the advantages of using a router table instead of a hand-held router for specific woodworking functions and about bits that are only used in the router table.

Relief carving is the process of cutting a pattern or design into a flat surface so that the design protrudes from the wood, which gives the piece a sense of depth. In this exciting, three-hour class, Ken will guide you through the process of carving a Celtic Knot using a variety of carving chisels. No experience required.

Sharp tools make all the difference in woodworking. However, it’s a fact that nearly all new woodworking chisels and plane irons are not ready to use. Once they’re properly sharpened, your woodworking skills will improve. In this class, you will learn how to put a truly keen edge on your tools using the Flat Sharpening method. We will teach you how to sharpen your chisels and plane iron blades. All you need to bring are typical tools you would like to sharpen; chisels or hand plane iron blades.

This is a introductory course to CNC. Students will learn the basic components of a CNC machine and fundamentals of how to design and machine a simple sign.

Get started at the lathe by learning the basics of spindle turning. In this exciting hands-on class you'll learn the skills required to start making spindles on the lathe as you turn two objects: a cove and bead stick and a vase. Tools covered include the roughing gouge, the spindle gouge, and the parting tool.

Learn how to select, sharpen and use one of the most misunderstood tools in the shop. Various types of hand planes, uses, tuning, sharpening and care will be covered. Bring your own hand plane or use one of ours.

This is a introductory course to VCarve software used for designing projects for CNC. Students will learn the fundamentals of creating and machining a project on CNC.

This class will teach the proper sizing of base cabinets, face frame construction, drawer construction and installation. The skills learned in this class will be Pocket Hole and Dado & Rabbet Joinery, installation of cabinet top using various methods. Tools to be used are pocket hole, routers, and table saw. A CABINET TOP IS OPTIONAL AND WILL BE AN ADDITIONAL $100.00 (Butcher Block Top)

This is the 2nd class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use layers, import files, edit vectors, manipulate text and combine multiple toolpaths into one file. The student will design and carve a picture.

Explore the possibilities of bowl turning as you learn to use a bowl gouge to turn your first bowl.

Featuring General Finish's new products. Wipe-on and brush-on both oil and water based finishes for the small-shop woodworker. The instructor will go over most of the General Finishes line of products with "how to prepare" instructions along with the advantages of the various products. In this class, you'll find out which finishes work best for particular applications, and how to apply them to achieve a lustrous sheen that begs to be touched and that scoffs at dirt and moisture.

This is the 3rd class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use Transform Function, dimension work, use guidelines, use Tabs, design and machine a gear.

This is the 4th class in the series and will advance the skill level of the student to use VCarve software. In this class the student will learn how to use design 3D project, import 3D objects, manipulate 3D objects, create a toolpath and machine a 3D model.

Want to take your CNC knowledge to the next level? Learn to enhance you CNC projects and signs with inlays using contrasting colors. In this class you will learn how to prepare your project for inlaying and creating the inlay to fit your project.