Jet

ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity - 1-3/4 HP 1 Ph 115V - JPS-10

Item #424376

Model JT9-725000K

Regular price

$1,999.99

Sale price

$1,999.99

Regular price

$1,999.99

Unit price

/

per

This item has an additional shipping charge

1

/

of

1

Jet

ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity - 1-3/4 HP 1 Ph 115V - JPS-10

Item #424376

Model JT9-725000K

Regular price

$1,999.99

Sale price

$1,999.99

Regular price

$1,999.99

Unit price

/

per

This item has an additional shipping charge

The Jet® ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity - 1-3/4 HP 1 Ph 115V - JPS-10 is a top-of-the-line table saw desi. . .

View More Details

Items you may need

-

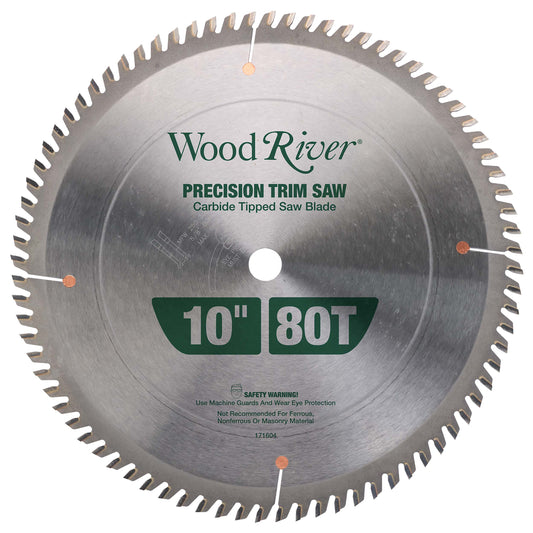

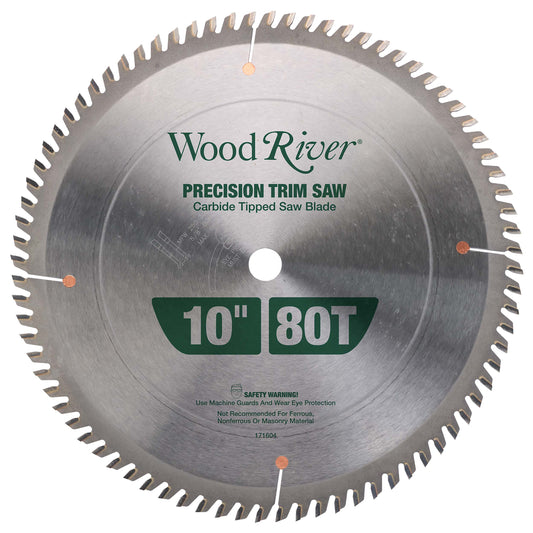

Precision Trim Saw Blade - 10" x 5/8" Bore x 80T - ATB

Regular price $109.99Sale price $109.99 Regular priceUnit price / per$109.99

-

Magnetic Stow Push Stick

Regular price $12.99Sale price $12.99 Regular priceUnit price / per$12.99

-

PushStick Hand Safety Device

Regular price $10.99Sale price $10.99 Regular priceUnit price / per$10.99

Details

The Jet® ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity - 1-3/4 HP 1 Ph 115V - JPS-10 is a top-of-the-line table saw designed for woodworking enthusiasts and professionals. With a powerful 1-3/4 HP motor and a 1 phase 115V power supply, this table saw is capable of handling even the toughest cutting tasks with ease. The cast iron wings and spacious 30" rip capacity provide ample surface area for cutting both large and small projects. The durable and adjustable T-square fence system allows for precise cuts and accurate measurements every time. The dust collection port helps keep your workspace clean and free of debris, while the blade guard and riving knife provide added safety.

Built to last and designed for maximum performance, the Jet® ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity is a must-have for any woodworking shop. It's perfect for home workshops, small businesses, and professional woodworking shops alike. Invest in the Jet® ProShop II 10" Table Saw today and experience the power, precision, and versatility of a top-of-the-line table saw. With its impressive motor, spacious cutting surface, and convenient features, this table saw is sure to become your go-to tool for all your woodworking needs.

Built to last and designed for maximum performance, the Jet® ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity is a must-have for any woodworking shop. It's perfect for home workshops, small businesses, and professional woodworking shops alike. Invest in the Jet® ProShop II 10" Table Saw today and experience the power, precision, and versatility of a top-of-the-line table saw. With its impressive motor, spacious cutting surface, and convenient features, this table saw is sure to become your go-to tool for all your woodworking needs.

Features:

- Quick release riving knife for hassle free riving knife changes

- Improved dust shroud around blade for better dust collection

- Convenient, magnetic paddle switch for the safest operation possible

- Innovative single belt design for easier belt tensioning and reduced vibration

- Motor reset switch conveniently relocated to the power switch instead of the motor

- Low profile riving knife included

- Redesigned guard for better protection and ease of use

- On board storage for all included accessories

- CSA certified

Specifications:

- Motor: 1-3/4 HP, 115V, 14.8A, 1 Ph

- Recommended Circuit Size: 20 Amps

- Dimensions: 43" H x 60" L x 40" W

- Table Height from Floor: 34-3/4"

- Maximum Depth of Cut at 45 Degrees: 2-1/8"

- Maximum Width of Dado: 13/16"

- Table Size: 20" L x 27" W

- Table in Front of Saw Blade at Maximum Depth of Cut: 8.81"

- Table Size with Extension: 44" L x 27" W

- Arbor Speed: 4000 RPM

- Maximum Rip Left of Blade: 13-1/2"

- Maximum Depth of Cut: 3-1/8"

- Miter Gauge Type: T-Slot with Stops

- Table Type: Cast Iron

- Arbor Diameter: 5/8"

- Dust Collection Minimum CFM Required: 350 CFM

- Maximum Rip Right of Blade: 30"

- Maximum Diameter of Dado: 8"

- Blade Diameter: 10"

- Dust Port Outside Diameter: 4"

- Gross Weight: 302 lbs.

- Net Weight: 276 lbs.

What's Included:

- (1) Jet® ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity - 1-3/4 HP 1 Ph 115V - JPS-10

Shipping / Billing Information

All shipments must be inspected and any damage reported within 3 days of receipt.

Address corrections and cancellations may not be possible once order is submitted. Requested changes may incur additional charges.

This product ships direct from the manufacturer:

- Your order will ship in 7-10 business days.

- This product is considered special order. Your account will be charged when you place your order.

- Express or overnight shipping is not available for this product.

- Ships by Ground to the 48 contiguous states. Cannot ship to Alaska, Hawaii, PO Boxes, APOs, US Territories, Canada or other foreign countries.

Return Information

All returns must be pre-approved. Any non-warranty returns must be unused and in original packaging. A 25% restock fee will apply. Customer pays return freight. Please call our Customer Service Dept. at 1-800-535-4482 with any return questions.

Instructions / MSDS

Reviews

Compare With

ProShop II 10" Table Saw with Cast Wings and 30" Rip Capacity - 1-3/4 HP 1 Ph 115V - JPS-10

Regular price

$1,999.99

Sale price

$1,999.99

Regular price

$1,999.99

Unit price

/

per

- Choosing a selection results in a full page refresh.

Favorite Your Store

Form field Zip or City is required. Please fill out the value.