Quickly shape and hone your edges

Work Sharp 3000

The Work Sharp is a horizontal disc sharpener that utilizes glass plates faced with pressure-sensitive adhesive (PSA) abrasives. The machine comes with two plates, so you can work through four grits, flipping or switching the plates as needed. Work Sharp sells the abrasives, but any 5" PSA sanding discs will work. The plate’s downward-facing side shapes and hones the bevel of chisels and plane irons up to 2" wide. An adjustable ramp guides the tool at standard preset angles, or you can determine your own. Setting a micro-bevel (a small, steeper bevel at the cutting edge) is as easy as resetting the ramp to a steeper pitch.

Flattening and honing tool backs happens on top of the plate. Topside is also where you shape and hone gouges (and wider tools). But with no jigging other than an adjustable height tool bar, achieving the desired angle requires eyeballing the bevel’s contact with the plate as the blade lies on the tool bar, and “rolling” it to sharpen. Work Sharp also includes a flexible, slotted disc with matching PSA sandpaper for sharpening other non-square tools from underneath, eyeballing their contact with the abrasive. While this sounds a bit odd, it works well. This machine was the easiest and fastest for honing bench chisels and plane irons. I was able to hone quickly and get back to work in under two minutes.

Bevel up from below. Slide the blade, bevel up, along the adjustable ramp, and into contact with the spinning disc. Apply pressure in short pulses to avoid overheating the tool steel. Fine abrasive covers the ramp’s surface for removing the burr on the back, but I preferred using the top of the plate as shown below.

Eyeballing underneath. Swap the glass plate for the plastic slotted one with its matching abrasive paper, and you’ll be able to see through the disc as it spins. This allows you to sharpen non-square tools such as skew chisels on the ramp or large lathe tools to the side by eyeballing how they contact the abrasive.

The bottom line:

Weight: 16 pounds

- Excellent for inexperienced sharpeners

- Fast, consistent sharpening of standard flat bench tools up to 2" wide

- Can hone and get back to work quickly

- Easy to flatten and hone tool backs

- Can sharpen wider blades and gouges but setting the bevel angle requires finesse

- Can sharpen lathe tools but lacks jigging for easy repeatability

- No capacity for honing the inside of gouges and veiners

- Ongoing abrasive costs

Veritas Mk.II Power Sharpening System

This horizontal disc sharpener from Veritas uses two-sided 8" diameter aluminum composite discs that are lighter and less fragile than Work Sharp’s glass plates but just as flat. All the sharpening happens topside. Shaping and honing the bevel requires using a series of included jigs and gauges. First, determine the angle using the bevel gauge and then set the height of the tool bar to match. Clamp the blade in the tool holder and set the projection as shown. Clip the tool holder to the tool bar, and pivot the blade down onto the spinning disc. Adding a micro-bevel requires removing a plastic spacer from under the disc, lowering it to create a steeper angle. With practice, I found mounting a chisel in the holder, then doing a touch-up honing was a two-to-three minute affair. Flattening the back of a rusted, pitted flea market find was much faster than doing it on a stone but used up three 80-grit discs. Sharpening gouges is done freehand as shown.

The bottom line:

Weight: 23 pounds

- Great for inexperienced sharpeners

- Works well for all standard hand tools, regardless of width

- 2-3 minute touch-up honing

- Compared to 5" discs, the 8" discs last longer, but they’re harder to find

- Easy and fast to flatten and hone tool backs

- Can sharpen gouges but setting the bevel angle requires finesse

- Can sharpen lathe tools but lacks jigging for easy repeatability

- No capacity for honing the inside of gouges and veiners

- Ongoing abrasive costs

Sorby ProEdge

Sorby is a leading manufacturer of woodturning tools, so it’s no surprise that their belt-sander-based sharpener excels at sharpening them. It comes with three belts, the finest of which leaves a nice edge for turning. To sharpen roughing gouges, roll them in the included gouge jig with the tool rest set for the desired bevel. For the specialized grinds on spindle and bowl gouges, remove the tool rest and clamp the tool in the fingernail profiling jig which slides on the lower tool bar.

The ProEdge also handles chisel and plane irons, but you’ll need to shell out an extra $100 for finer-grit belts (600, 1200, 3000) and maybe their Square Guide. To sharpen the bevel, angle the tool rest using Sorby’s clever system of holes that make this easily repeatable. Hold the blade bevel down, against the guide, and on the rest. Then advance it into the belt. Repeat this process through the grits In use, I found it took longer to change the belts (1-2 minutes) than it did to do the actual sharpening (<30 seconds per grit). To flatten and polish the back, hold the chisel against the belt as shown. This unit didn’t produce as clean a polish on flat tools as the other machines. For sharpening carving gouges and veiners, a buffing wheel is available for polishing the insides of the flutes.

Tilt and polish. You’ll need access to the backside of the machine when it’s time to hone the back of your flat tools. Tilting the belt to a comfortable position requires loosening two Allen screws and then retightening to lock it in place.

Angle and abrade. The Proedge’s tool rest is similar to a high-end rest for a bench grinder with the added benefit of a precise angle setting system. The only drawback is that it doesn’t accommodate chisels with short blades.

The bottom line:

Weight: 36 pounds

- For serious turners who also do some flat woodworking (requires additional accessories)

- Accessories available for specialized turning grinds as well as kitchen knives etc.

- Touch-up honing of both turning and flat tools in under 1 minute

- Adds a nice, small belt sander to your shop

- Hard to hone the back of flat tools to a mirror

- Ongoing expense for belts

Tormek T-8

Tormek is so confident that their machine produces scary sharp tools that they include a pack of Band-Aids, “just in case.” They’ve put a lot of thought into how to sharpen everything from woodworking tools to kitchen knives and garden implements. If it has a cutting edge, you can probably sharpen it on a Tormek with the appropriate accessory jig. Be aware, however, that the machine comes only with the holder for sharpening chisels and plane irons. The sharpener consists of a low-speed motor turning a 10" diameter waterstone on one side and a leather-rimmed honing wheel on the other, both of which are replaceable and upgradable. Flatten the back of flat tools on the side of the wheel as shown. For the bevel, mount the tool in the holder, and set the angle with the help of the included bevel gauge. Place the F-shaped tool bar in the appropriate position, and mount the tool holder. Then press the bevel against the spinning wheel. Since the wheel runs in water, there is no risk of overheating the steel. To hone, move to the leather-faced honing wheel. The T-8 takes some getting used to, but the instructions—and results—are excellent. Once I had the machine set up, it took about 20 minutes to take a new chisel from its factory grind to joinery-ready my first time out. Subsequent touch-ups took two–to–three minutes.

Hone to perfection. After charging the leather with the provided honing compound, reposition the tool bar and keep the tool in the holder as you hone the bevel. Polishing the back is done freehand.

Keep your cool. Tormek’s water bath makes bluing tools impossible. Beware that the stone may crack if it freezes when wet.

The bottom line:

Weight: 33 pounds

- A system to grow with

- Comes ready to sharpen long plane irons and bench chisels

- Designed to sharpen all tools well

- Jigs, holders, and honing wheels available for tools including:

- Turning tools

- Carving tools

- Jointer and planer knives

- Kitchen knives

- Garden tools

- Hatchets and axes

- Scissors

- Drill bits

- Pizza cutters

- Includes a carry handle

- Minimal ongoing expenses

Two Special Systems

The final two systems are actually add-ons for bench grinders: Razor Sharp’s Edgemaking System and Oneway’s Wolverine Grinding Jig. Razor Sharp’s system features two paper wheels—one for shaping and the other for honing—that fit your grinder. The company recommends a high-speed grinder (3600 RPM), but I found that a slow-speed (1800 RPM) model gave me more control. The system works well, but without a means to hold tools at specific angles, sharpening bench chisels and plane irons becomes problematic. Nevertheless, it worked very well for sharpening knives and maintaining the edges on my straight carving tools gauging the bevel angles by eye.

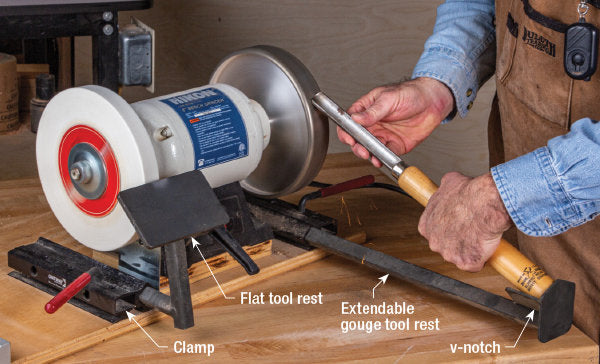

Oneway’s Wolverine Grinding Jig is designed to sharpen turning tools. It consists of two interchangeable tool rests that fit into clamps mounted beneath your grinder’s wheels. One of the tool rests offers a wide, flat surface for sharpening scrapers and other flat tools. The other tool rest is a extendable arm with a v-notch at its end. By registering the handle end of your gouges in the notch and setting the rest at a consistent distance away from the grinder, it’s a simple matter of rolling the tool to get a fast, consistent edge. Other jigs are available for specialized grinds on bowl and spindle gouges and skew chisels.

Paper wheels. Razor Sharp’s system is based on two laminated paper wheels that provide a firm surface and hold up surprisingly well. The rim of one gets charged with abrasive grit for shaping; the rim of the other, with white diamond buffing compound.

Freehand buffing. To avoid damaging the paper wheels, hold your tools cutting-edge down. No gauge or tool rest required; simply grind and buff the bevels by feel.

The bottom line:

Razor Sharp Edgemaking System

- Works with your existing grinder

- Great for knives and straight carving tools

- Incompatible with most grinder tool rests

Wolverine Grinding Jig

- Works with your existing grinder

- Great for turning tools

- Additional jigs available for specialized grinds