Get your wood supply organized with a sturdy steel system that mounts on the wall

Managing the lumber supply can be a challenge in any woodshop, but it’s a problem worth solving. Otherwise, you end up misplacing boards and working around wood that’s stealing valuable floor space. Offcuts and other short pieces can often reside in boxes or barrels, but what about your longer stock? While shop-made lumber racks have always been popular, this storage assignment can also be handled by heavy-duty hardware.

The shelving systems featured here have what it takes to quickly put a bare wall to work, providing sturdy racks that will help keep your boards in order. Choosing the system that’s right for your shop will depend on the wall space you have available, your budget, and how much flexibility you need from the system. All of these systems feature steel standards (aka uprights) that must be anchored securely to the wall and brackets (shelf supports) that lock in place on the standards. The systems are easily expandable; you simply add more standards and brackets.

Basic standard-and-bracket systems are simple, strong and easy to install

With these systems, you get a basic shelving module that includes two uprights and the shelf supports to go with them. Only one bracket length is available for each system, but a 12" shelf provides plenty of capacity for most lumber. If you're looking for a fast, easy storage solution, these kits don’t disappoint. Open the box, grab a level and your cordless driver, and put your wall to work. See the Buyer’s Guide on page 76 for ordering information.

WoodRiver HD Shelf System, $89.99

WoodRiver HD Shelf System, $89.99

Capacity: 3 shelves; 400 lbs. max. per shelf.

Installation & use:

Don’t let the small size of this system put you off. It has some useful features. Use a single set of uprights and brackets if you have limited wall space. Need more storage? No problem. Uprights can interlock to make taller racks, as shown above. Cotter pin holes in the uprights enable you to adjust bracket height in 6" increments. I like the fact that the brackets are angled slightly upward, a feature that will help prevent narrow boards and warped stock from falling off the rack. But the system’s most useful feature is likely to be bracket pivoting ability. In just a few seconds, you can lift a bracket off its cotter pin support and pivot the bracket back against the wall, where the cotter pin will hold it in place. If you need temporary clearance in your shop for furniture, tools or other stuff, you can essentially “fold” all or part of your lumber rack against the wall.

Components:

Portamate 6-Shelf Wood Rack, $74.99

Capacity: 6 shelves; 110 lbs. max. per shelf.

Installation & use:

Interested in maximum shelf space for minimum dollars? If so, look no farther. The Portamate system is definitely a no-frills design, with fixed, equally spaced positions for brackets. But you’re getting six separate shelving levels for your lumber. While you could delete one shelving level to create a taller stack space, this might not be a good idea considering the 110 lb. weight limit for each shelf. Portamate’s approach to wood storage makes sense: closely spaced shelves that hold a limited lumber supply on each level. This storage strategy avoids overloading and shortens sorting time.

Components:

Slotted standards offer adjustability & workbench capability

For storage you can customize to suit your needs, these two systems let you order a la carte. Thanks to a good selection of components, you get the flexibility to handle all kinds of lumber storage, and more. Standards come in a different lengths, and their slotted design makes it easy to position support brackets exactly where you want them. Bracket choices are equally impressive, ranging from 10" to 18" for one system and 10" to 20" for another. Yes, those larger brackets have the length and strength to support a tabletop–a great option if you need another work surface but don’t want to build or buy a workbench.

Low-profile lumber storage system, $230 (as shown)

Low-profile lumber storage system, $230 (as shown)

Capacity: 300 lbs. max. per shelf

Installation & use:

Components in this system have a different look and feel. Everything is made from 3⁄16"-thick steel that has a thick, rough, galvanized coating. With its rugged design and rust-resistant treatment, this shelving would probably outlast others in outdoor conditions. The entire system has a low-profile design. Standards extend just 1⁄2" from the wall, and brackets have a shallow, U-shaped form. The 14" and 18" brackets can support a work surface if you want to go that route. To make a taller storage rack, you can interlock shorter standards. There’s one installation quirk worth noting: You’ll need 1⁄4" or 3⁄8"-dia. lag screws and washers to install brackets because of oversize holes where the screws need to fit (inset photo, above).

Components:

Heavy-duty galvanized shelving system, $86 (as shown)

Heavy-duty galvanized shelving system, $86 (as shown)

Capacity: 300 lbs. max. per shelf

Installation & use:

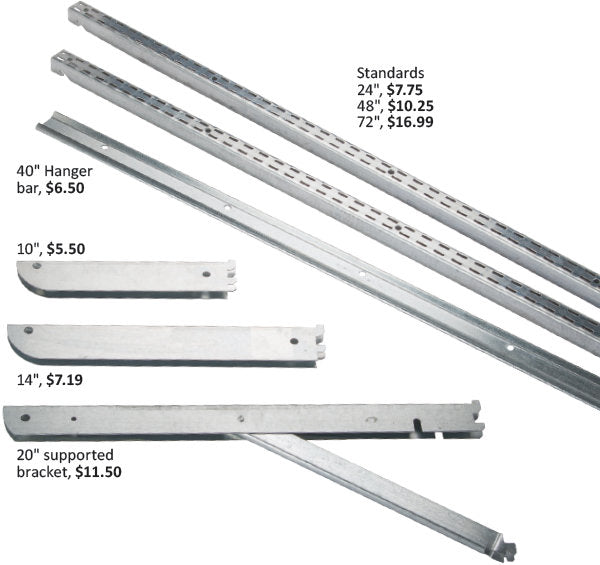

This system wins the prize for versatility, mainly because you’ve got the largest selection of standards and brackets. Several years ago, I installed a storage rack/workbench combination using this system, supporting a 22"-deep, 8'-long countertop on the 20" brackets. As shown in the photo at right, longer brackets gain extra support by means of diagonal braces that clip into standard slots–a nice feature. The hefty standards jut out from the wall about an inch, so there’s some loss of space before you get to the shelf supports. But the system earns extra points for ease of installation, thanks to hanger bars that can be installed horizontally on the wall to provide a mounting tab for the standards. If you mount the hanger bars level across the wall (making sure to fasten into solid masonry or wood framing), your standards can be spaced anywhere along the hangers – they don’t need to be individually set to the same height. Plan on driving two more mounting screws lower down in each standard to keep it plumb and secure.

Components:

Don’t forget the fasteners

None of these systems include fasteners for mounting standards on the wall. But you won’t have trouble finding lag screws or heavy-duty wood screws for installation. In a wood-framed wall, at least half the fastener’s total length should extend into the framing. For installation on a masonry wall, make sure to use masonry anchors with a load rating that’s comparable to what your storage system is rated to hold (see the capacity details given for each system). The spacing between each standard can be anywhere between 4' and 6', but it’s smart to stay closer to 4' so that short or thin boards don’t sag.